Gas Engine & Gas Generating Set

Engine Specifications

| Model | Unit | G1012L | G1012LA | G1016L | G1016LA |

|---|---|---|---|---|---|

| Bore | mm | 275 | |||

| Stroke | mm | 300 | |||

| No. of cylinders | 12 | 16 | |||

| Displacement | L | 214 | 285 | ||

| Speed | r/min | 1000 | |||

| Brake power | kWb | 2400 | 2105 | 3160 | 2842 |

| Max de-rate altitude | 2 | 2000 | |||

| Engine rotation | CCW(facing flywheel) | ||||

| Fuel Consumption | |||||

| @100%Rating power | MJ/kWh | 9.05 | 9.70 | 9.05 | 9.63 |

| @75%Rating power | MJ/kWh | 9.39 | 10.08 | 9.39 | 10.00 |

| Lub oil consumption | g/kWh | 0.35 | |||

| Engine JW capacity | L | 460 | 550 | ||

| Engine AW capacity | L | 160 | 180 | ||

| Total lub oil capacity | L | 890 | 1280 | ||

| Oil change interval | h | 4000 | 3500 | 4000 | 3500 |

| Fuel Supply Pressure | kPa | 360~450 | 3~12 | 360~450 | 3~12 |

| Starting pressure | MPa | 0.7~1.0 | |||

| Control system | AXXEN I | ||||

| L×W×H | mm | 4739×2230×3179 | 5176×2076×3055 | 5659×2266×3179 | 6096×2266×3055 |

| Engine dry weight | kg | 23900 | 24900 | 29600 | 30800 |

Notes:

G-Gas Engine

L-Lean burn Post-turbo Carburetion

LA-Lean burn Pre-turbo Carburetion

Engine Technology Data

| Model | Unit | G1012L | G1012LA | G1016L | G1016LA |

|---|---|---|---|---|---|

| Emission | |||||

| NOx @5% O2 | mg/Nm³ | 250 | 250 | 250 | 250 |

| CO @5% O2 | mg/Nm³ | 720 | 720 | 700 | 700 |

| NMHC @5% O2 | mg/Nm³ | 290 | 290 | 260 | 260 |

| THC @5% O2 | mg/Nm³ | 2920 | 2920 | 2600 | 2600 |

| Heat Balance | |||||

| Heat Rejection to Jacket Water | kWb | 604 | 573 | 913 | 857 |

| Heat Rejection to Intercooler | kWb | 478 | 495 | 628 | 651 |

| Heat to Lube Oil | kWb | 216 | 210 | 395 | 410 |

| Heat to Exhaust | kWb | 2182 | 2175 | 2657 | 2639 |

| Air & Exhaust | |||||

| Induction Air Flow | Nm³/h | 12951 | 11812 | 17923 | 16628 |

| Exhaust Gas Flow Rate | kg/h | 16733 | 15262 | 23840 | 22108 |

| Temp After Turbocharger | ℃ | 450±30 | 460±30 | 430±30 | 440±30 |

Rating and definition

Performance and data are under ISO 3046/1-1995 conditions and terms with commercial quality natural gas having SLHV 33.6MJ/Nm³;

All data are average at standard condition and may vary for individuals, site condition, fuel quality change and necessary adjustments on air fuel ratio, ignition timing etc. may have affection to engine performance.

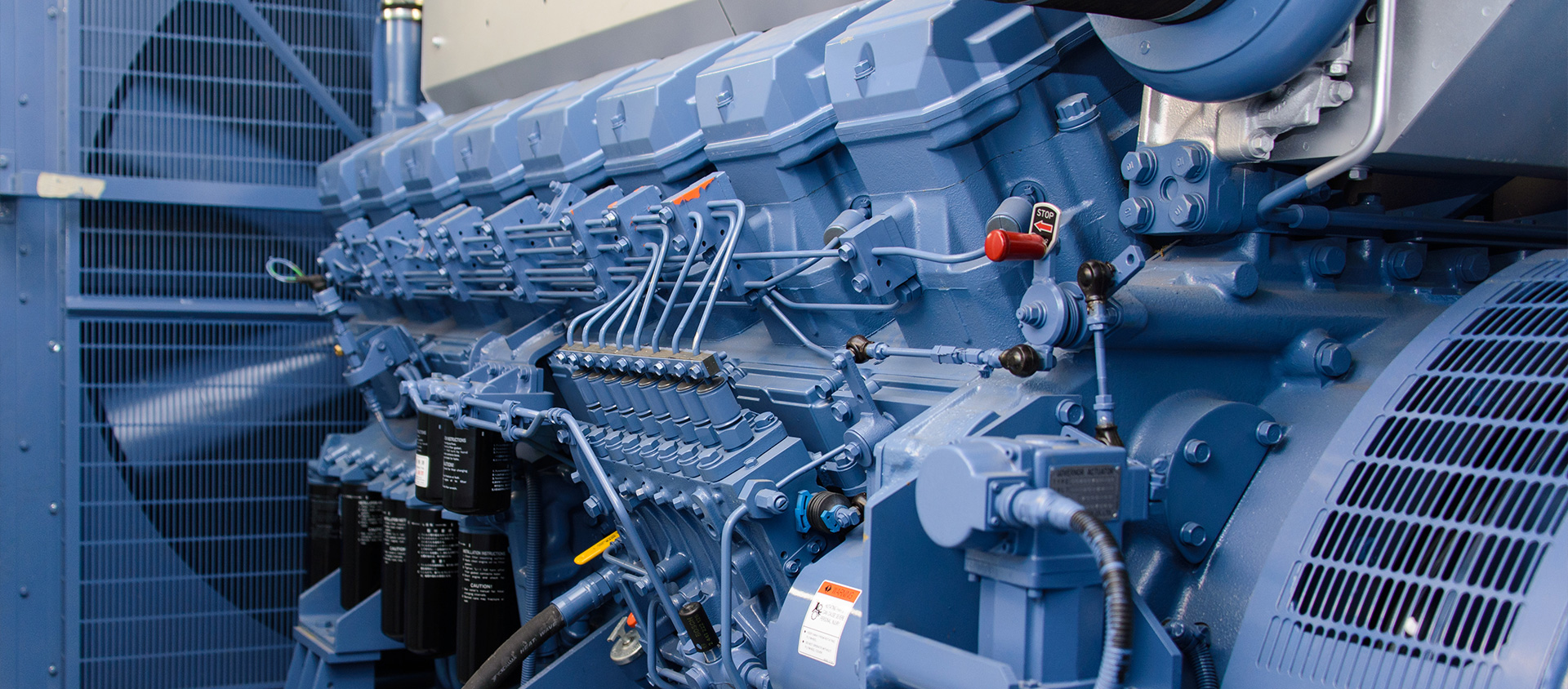

Engine Features

Engine Design

- Proven reliability and durability

- Able to run wide range of gaseous fuels with MN greater than 45

- Robust diesel strength design prolongs overhaul interval and lowers operating costs

- Broad operating speed range

- NOx emissions below 250 mg/Nm³

- Applicable to both low and high fuel pressure

Lean Burn Combustion Technology

Lean-burn engine operates with much larger amount of excess air than traditional rich burn engine. The excess air absorbs heat during combustion reducing combustion temperature and pressure, thus greatly reducing NOx emission, prolonging component life and reducing fuel consumption as well.

Easy Operation

- High strength skid for excellent mounting and stability

- Clear sides for easy inspection, operation & maintenance

User Friendly AXXEN Controls

Huaqi Power Controls integrate most necessary engine controls include start/stop sequence, speed, air/fuel ratio, Turbocharger, radiator cooling fan, safety and data log/transmission in one system simplified user interface, display, start/shutdown controls, and system diagnostics.

Easy Installation/Packaging

Most necessary accessories are engine mounted for easy installation and packaging.

Ex-work Test

Each engine is fully tested to ensure proper engine performance.

Air Inlet Connection

– Differs with low/high fuel system, consult for details.

Exhaust Manifold

– Dry with protective insulation.

Exhaust Outlet

– Two horizontal outlet flanges.

CRANKCASE

– Single iron casting, stress relieved. Main bearing caps are retained with vertical studs and lateral bolts.

CRANKCASE PRESSURE RELIEF DOORS

– 6 or 8 mounted on both side of crankcase.

CRANKCASE VENT CONNECTION

– 3 inch round tube connection

CONNECTING RODS

– Low alloy forged, fully machined.

CAMSHAFT

– One per cylinder interchangeable, bolted together.

CRANKSHAFT

– Low alloy forged, fully machined, 100% balanced.

CYLINDER HEAD

– One for each cylinder interchangeable. Each head with two intake and two exhaust valves, water cooled valve seat.

CYLINDER LINER

– Removable wet type.

PISTON

– Aluminum alloy casting.

TURBOCHARGER

– One per cylinder row, fitted with an exhaust gas bypass valve and air bypass valve controlled by an AXEEN I system

INTERCOOLER

– Air–to–water, up to 50° C inlet water.

CONTROL SYSTEM

– AXXEN Control I.

GOVERNOR

– Electronic governor and actuator controlled by AXXEN control I.

FUEL SYSTEM

– Both low and high pressure fuel system are available. Both systems are Venturi carburized.

IGNITION SYSTEM

– Programmable Ignition module with function of manual test.

LUBRICATION SYSTEM

– The system include components below: Gear type and gear driven pump with pressure regulator and bypass circuit, plate type oil cooler and full flow lube oil filters, centrifugal oil bypass filter, electric pre/post lube pump.

STARTING SYSTEM

– One turbine pneumatic starter requires 0.7- 1.0MPa air/gas supply.

VIBRATION DAMPER

– Geislinger damper mounted on front end of crankshaft.

BARRING DEVICE

– Manual.

Screen Monitor

– Factory programmed include:

Monitoring parameters:

Power, Speed, Pre/post filter oil pressure, oil header temp, JW temp, AW temp, intake temp, intake pres., cylinder exhaust temp, pre/post turbo temp, main bearing temp, G/A pressure, prechamber pressure, generator bearing temp, etc.

Protection devices and settings

– Emergency shutdown buttons physically mounted on each side of engine: emergency shutdown also provided on control screen. System protection include: lube oil pres. and temp, intake manifold temp, overspeed, JW temp, Main bearing temp, generator bearing temp, etc.

Flywheel

– 291 tooth ring gear with flywheel guard.

Paint

– AXXEN red.

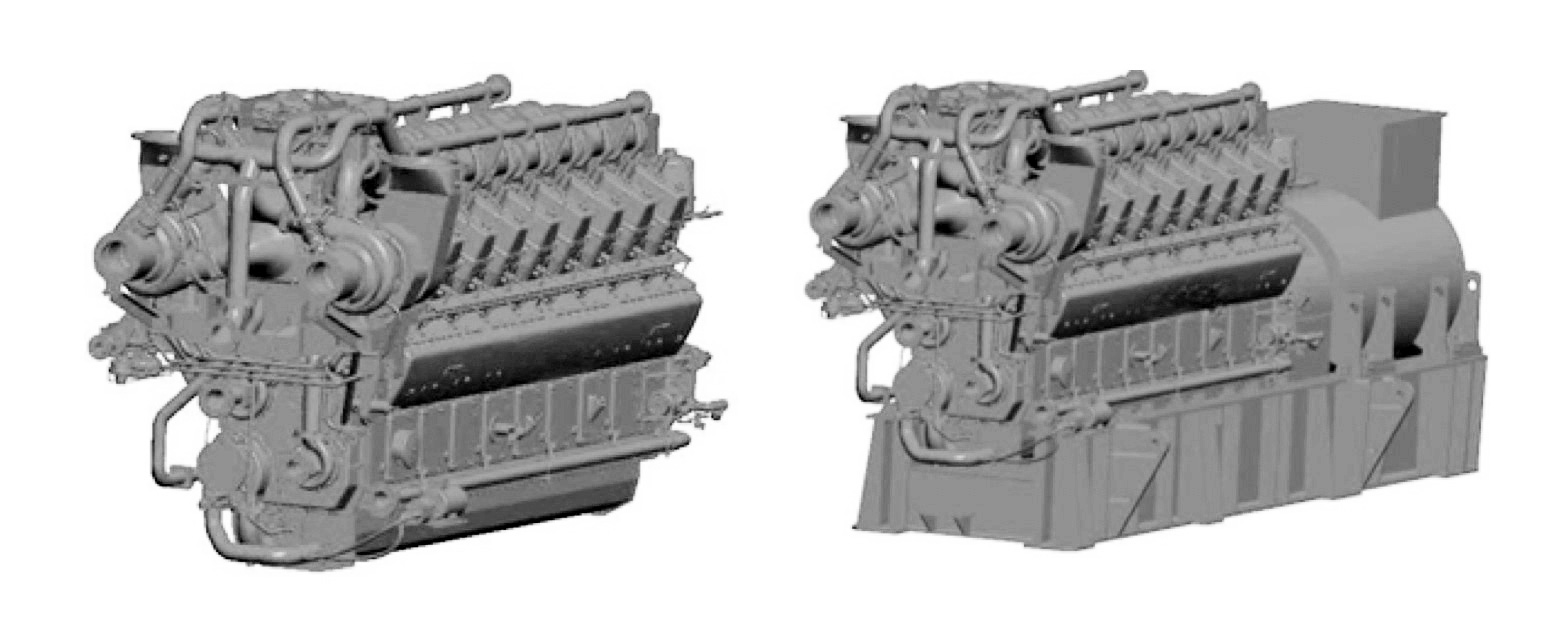

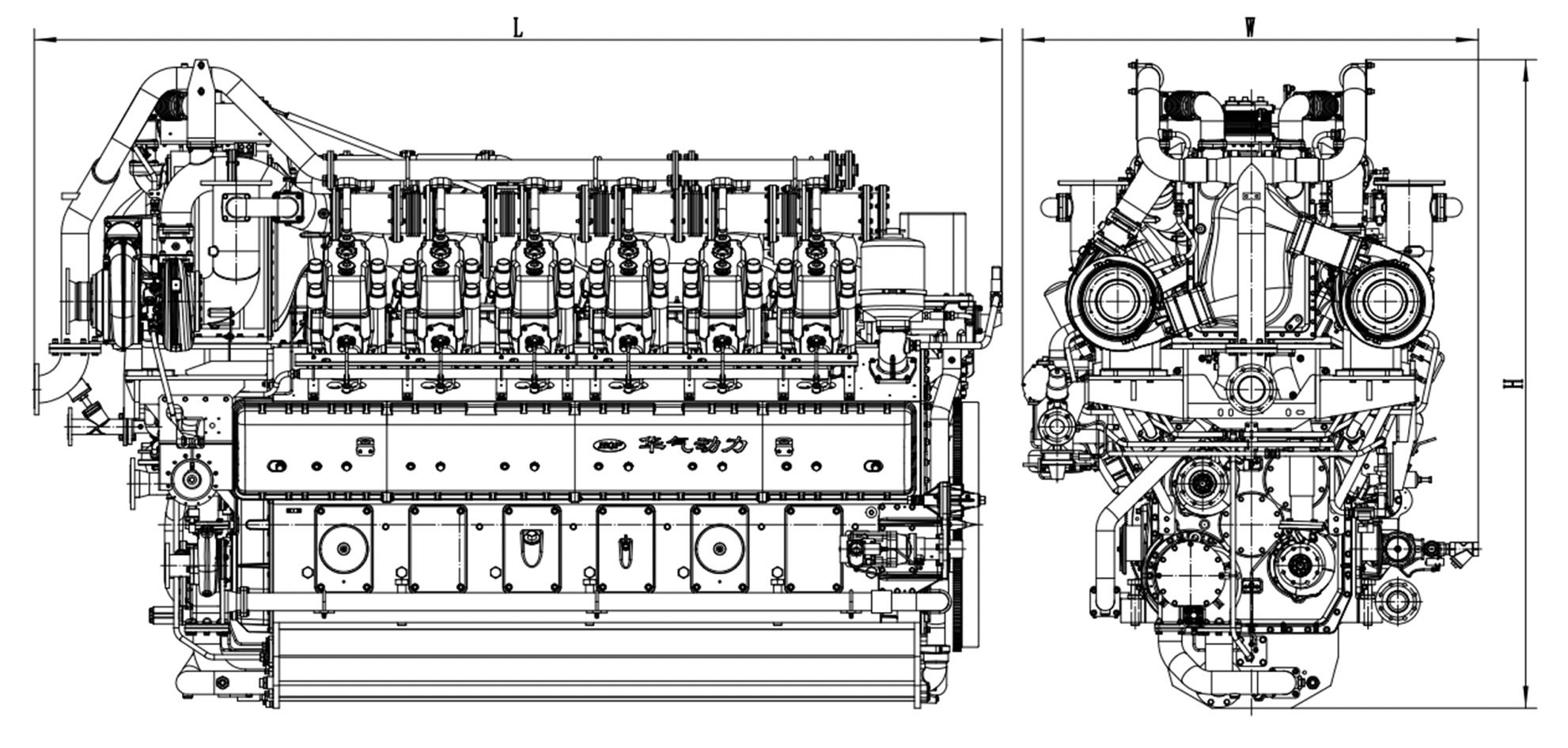

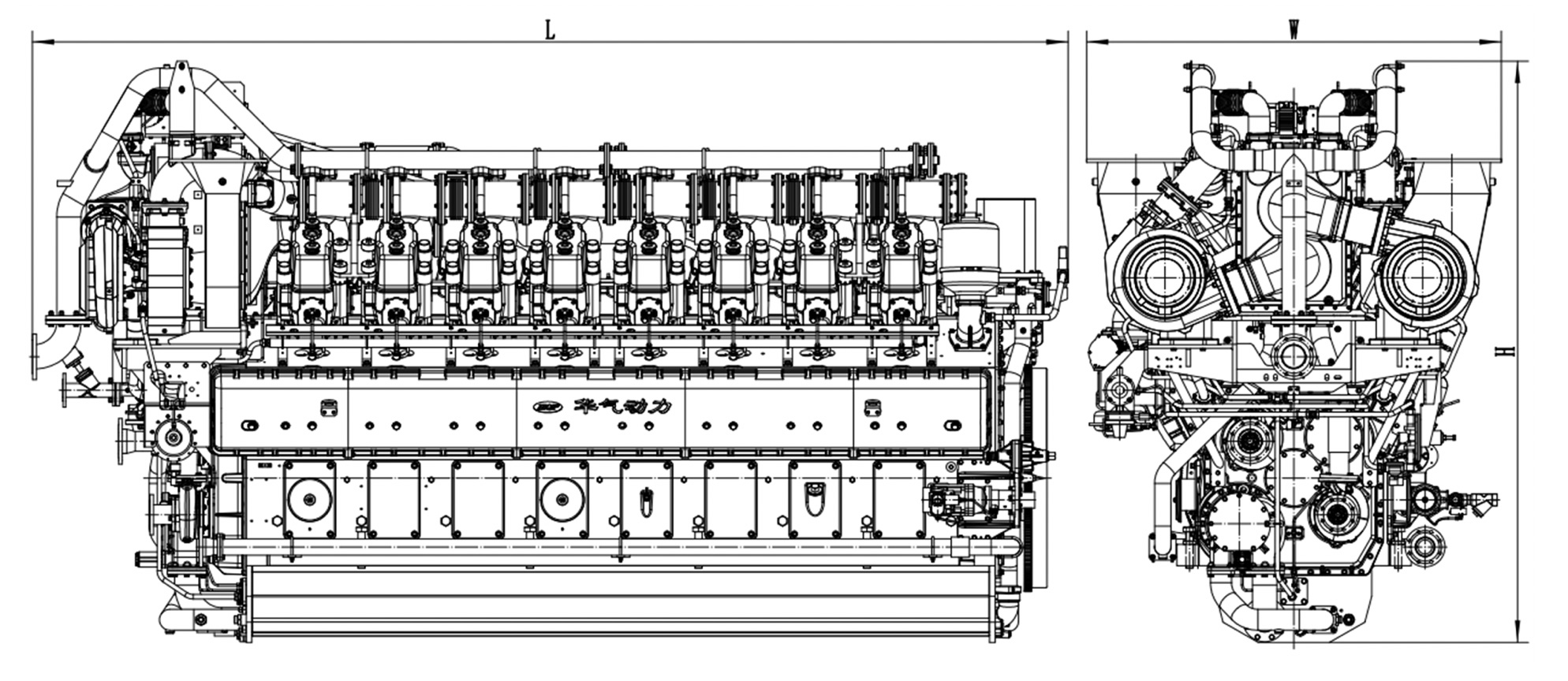

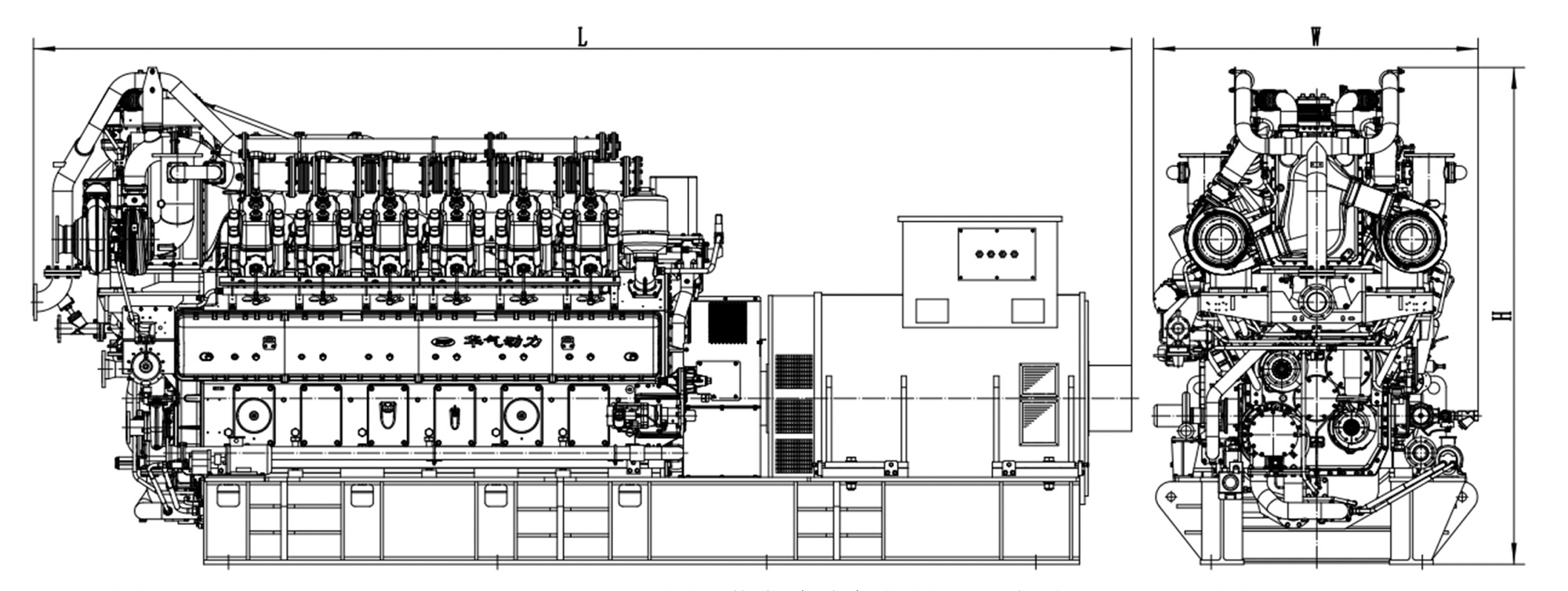

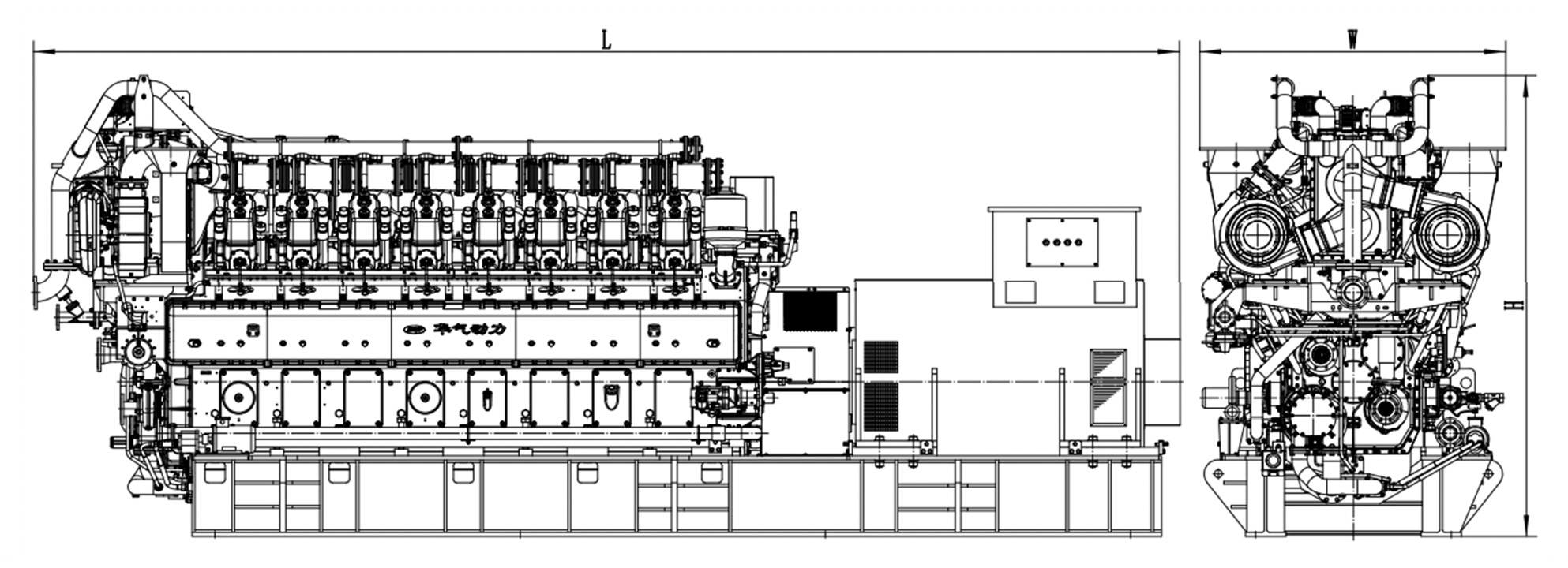

Engine Overall Dimension

G1012L/LA Gas Engine Overall Dimensions

G1016L/LA Gas Engine Overall Dimensions

Generator Set Specifications

| Model | Unit | G1012L-2000 | G1012LA-2000 | G1016L-3000 | G1016LA-3000 |

|---|---|---|---|---|---|

| Rated Power | kWe | 2250 | 2000 | 3000 | 2700 |

| Output Voltage | kV | 6.3 / 10.5 | 6.3 / 10.5 | 6.3 / 10.5 | 6.3 / 10.5 |

| Genset efficiency | % | 37.8 | 35.3 | 37.8 | 35.5 |

| L×W×H | mm | 7550×2230×3425 | 7986×2215×3300 | 8490×2266×3425 | 8923×2266×3300 |

| Dry weight | kg | 38700 | 39700 | 48600 | 49800 |

Generator Set Overall Dimension

G1012L/LA-2000 Gas Generator Set Overall Dimensions

G1016L/LA-3000 Gas Generator Set Overall Dimensions

Fuel Gas Specifications

| Description | Unit | NG | Landfill gas | CMG | Process gas | Bio gas |

|---|---|---|---|---|---|---|

| Inlet temp. | ℃ | -10~+40 | ||||

| Inlet Pres. | kPa | 360~450 | 3~12 | 3~12 | 3~12 | 3~12 |

| Pres. swing | kPa/min | ≤5 | ≤1 | ≤1 | ≤5 | ≤5 |

| Heat swing | %/min | ≤2 | ≤5 | ≤2 | ≤5 | ≤5 |

| Full load MN requirement | MN | 70/50* | ||||

| CH4 vol. content | % | ≥90 | ≥35 | ≥6 | ||

| CH4 vol. swing | %/min | ≤2 | ≤2 | |||

| H2 Vol. content | % | ≤12 | ≤12 | |||

| Water & moisture | Humidity ≤100%, no condensation permitted | |||||

| Solid particulate matter (SPM) | μm | ≤5 | ||||

| SPM content | mg/Nm³ | ≤20 | ≤10 | ≤2 | ≤10 | ≤10 |

| Total sulfur | mg/Nm³ | ≤100 | ≤70 | ≤20 | ≤30 | ≤70 |

| H2S content | mg/Nm³ | ≤50 | ≤35 | ≤10 | ≤15 | ≤35 |

| NH2 content | mg/Nm³ | ≤10 | ≤10 | |||

| Siloxane content | mg/Nm³ | ≤10 | ||||

| Liquid hydrocarbon | mg/Nm³ | ≤100 | ||||

| THC | mg/Nm³ | ≤100 | ≤100 | |||

| * AXXEN offers different combustion system for different fuel gas based on fuel MN, the lowest allowable MN is 50. Please consult AXXEN tech department for specific project. Notes: Any items not listed please consult AXXEN tech department. |

||||||

Materials and specifications are subject to change without notice.