-

>75%

of global CO₂ emissions in the energy sector are caused by coal power plants

-

up to 70%

CO₂-emissions reduction potential by repowering

-

up to 30%

less CAPEX by repowering in comparison withnew build plant

-

>75%

H₂-cofiring capability in repowered power plants

-

>300%

faster plant start-up and shut-down for improved operational flexibility

Above figures are estimates

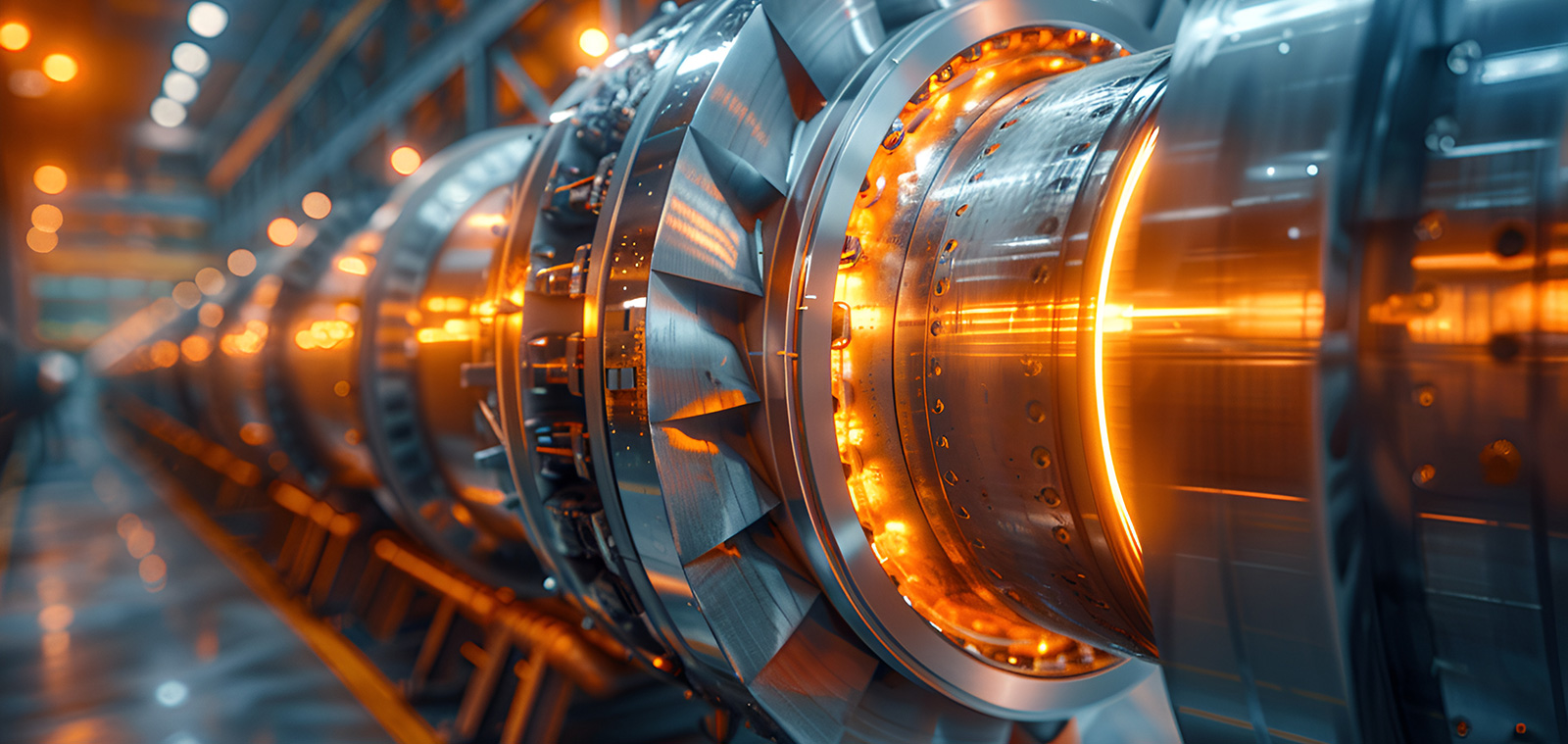

Today increasingly ambitious CO₂ targets are being set around the world. Reaching them won’t come about by itself. Apart from intelligent energy management and improved energy efficiency, we need to decarbonize power generation for utilities and industry. And since we can’t rebuild energy generation from scratch, assets viewed as burdensome today, such as coal power plants, must be repurposed as bridges to a new energy future. It’s called Brownfield Transformation: Converting existing power plants, so they help us reach the decarbonized economy we all aim for.

The road to decarbonization for fossil generation units

Coal- / oil- / gas-firedsteam turbine plant

Current status

Fuel shift / repowering / conversions

Increase efficiency

Hybridization of existing power plant

Integrated solution

Net zeroenergy systems

Target scenarios

No matter which solution you choose for your brownfield power plant conversion, there are numerous potential benefits: avoiding stranded assets; less investment compared to greenfield projects; shorter implementation time, including fewer permits to apply for. At the same time, you may even open new revenue streams. Apart from these advantages, brownfield conversion could also help further your reputation while you contribute to the common good. Altogether, not only will you support decarbonization efforts, but continuing to employ qualified personnel can also significantly ease socioeconomic strains on local communities.

Coal-to-gas conversion by repowering

- Up to 70% reduced CO₂ emissions along with significantly improved efficiency*

- Up to 30% reduced Capex compared to greenfield*

- Ready for H₂ co-firing and potential for further hybridization

- Operational flexibility from 20% to 100% plant capacity

- Reuse existing infrastructure, permits and plant equipment

- Improved plant profitability by increased efficiency

- *Note: Above figures are estimates

Rotating grid stability conversion

- Essential for maintaining grid stability in an age of renewables

- Supplying system inertia, short-circuit power and reactive power

- compensation for voltage control

- Reuse existing grid connection, permits and plant equipment

- New and additional revenue streams

- Short implementation time and Capex advantage compared to greenfield

Hybridization with integrated solutions

- Main enabler for sector coupling

- Enabling new revenue streams by using existing and new assets

- Technology integration and implementation independent of OEM

- Increased operational flexibility

- Significant cost savings and reduced life cycle CO₂ emissions thanks to up to 70% reusability

Modernizations & upgrades

- Lifetime extension for longer maintenance intervals and sustainability

- Efficiency and power increase through high-performance upgrades

- Improved operational and maintenance flexibility

- Potential for reduced CO₂ emissions overall

Brownfield engine exchange

- Plug-and-play concept for replacing existing gas turbines with new ones

- Maintain existing steam cycle

- Increased power output, improved efficiency, and operational flexibility

- H₂ co-firing

- Potential CO₂ savings

Industry plants & applications

- Repowering power plants with Combined Cycle plants

- Optimizing efficiencies by smart integration

- Hybridization with energy storage, H₂-generation